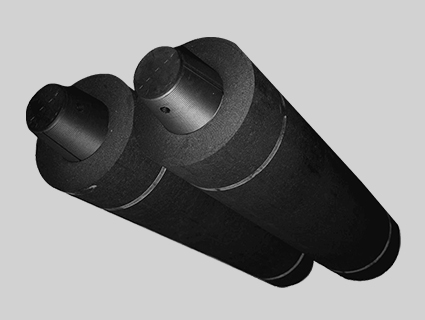

MAVEN supply UHP/HP/RP Graphite Electrode with diameter 75mm-700mm for steelmaking and ferroalloy smelting.

Size: 300-750mm

Size: 75-700mm

Size: 75-700mm

Size: customizable

Size: 5-10mm

Efficient, sustainable, and cost-effective: choose our graphite electrodes for your production needs

Take 100% needle coke as raw material on the production of UHP graphite electrode

Ensure low unit consumption to reduce end user’s production cost

Imported needle coke brand: Conocophilips, Mitsubishi, etc.

Committed to improving product performance

| Item | Unit | RP | HP | UHP | ||

|---|---|---|---|---|---|---|

| φ75-φ700mm | φ75-φ700mm | φ300-φ500mm | φ500-φ700mm | |||

| Resistivity | Electrode | μΩm ≤ | 7.0-10.0 | 5.8-6.6 | 4.8-5.8 | 4.6-5.5 |

| Nipple | 4.0-4.5 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | ||

| Modulus of Rupture | Electrode | MPa ≥ | 8.0-10.0 | 10.0-13.0 | 10.0-14.0 | 10.0-14.0 |

| Nipple | 19.0-22.0 | 20.0-23.0 | 22.0-24.0 | 22.0-26.0 | ||

| Young’s Modulus | Electrode | GPa ≤ | 7.0-9.3 | 8.0-12.0 | 9.0-13.0 | 10.0-14.0 |

| Nipple | 12.0-14.0 | 14.0-16.0 | 15.0-18.0 | 16.0-19.0 | ||

| Bulk Density | Electrode | g/cm³ ≥ | 1.53-1.56 | 1.64-1.68 | 1.68-1.74 | 1.70-1.74 |

| Nipple | 1.70-1.74 | 1.75-1.80 | 1.78-1.82 | 1.80-1.84 | ||

| C.T.E. (100-600℃) | Electrode | 10-6/℃ ≤ | 2.2-2.6 | 1.6-1.9 | 1.1-1.4 | 1.1-1.4 |

| Nipple | 2.2-2.5 | 1.1-1.4 | 0.9-1.2 | 0.9-1.2 | ||

| Ash Content | % ≤ | 0.3 | 0.3 | 0.3 | 0.3 | |

Strict management in testing resistivity, weight, checking appearance and packaging,

to ensure that all goods are delivered to customers in good condition.

Comprehensive pre-sales, in-sales, and after-sales services to ensure a seamless customer experience, which offerings set us apart.